Content

Videos

QUESCREM PLUS, A UNIQUE CREAM CHEESE

There are other cream cheeses on the market, but none of them meet all 3 of the key features for both industry and the professional:

- + Cold Dosification Ability

- + Stability to Freezing – Thawing

- + Resistance to Extreme Heating

Quescrem plus can be adapted in flavor or in texture according to the needs of the customer:

- The texture after heating can be varied from creamy to very consistent

- The current range of available flavours is: Natural, Garlic & Herbs, Tomato & Basil, Chives, Camembert cheese, cured cheese, goat cheese, blue cheese and cheddar

Possible applications:

- Toppings. Pizzas.

- Hot sandwiches.

- Bakery & Pastry Fillings (including small size)

- Small pastries and croquettes.

- All type of uses which requires easy aplicattion, freezing and heating.

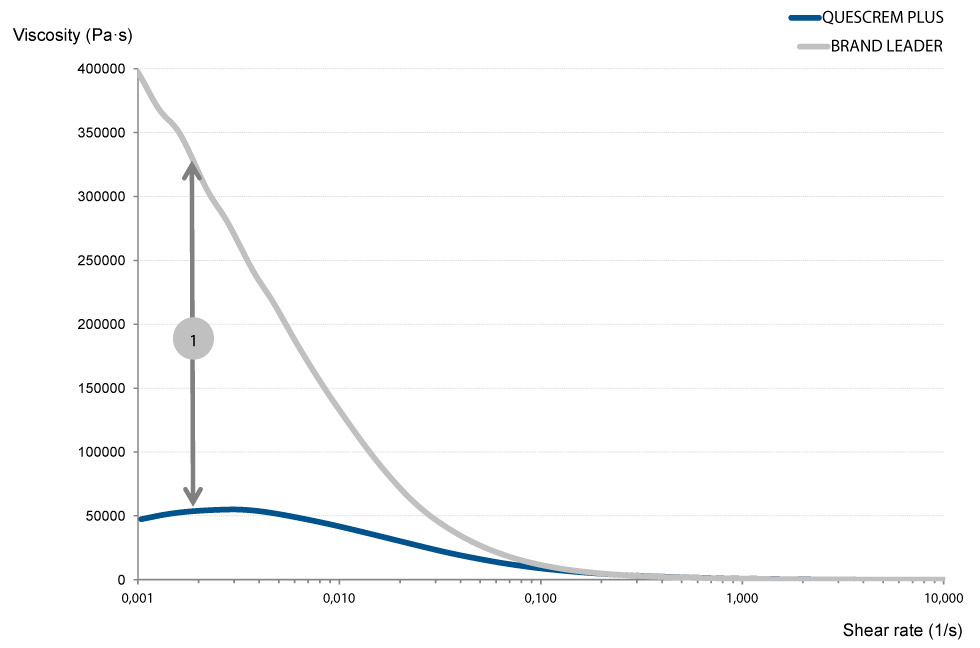

EASY COLD APPLICATION & PUMPING

At refrigeration temperatures, (2 – 6 ºC), the cheese has a soft and creamy texture with no dripping, allowing it to be applied and pumped by mechanized systems without the need to softened, whip or mix with other liquid ingredients

CREATED WITH THE INDUSTRY IN MIND!

Advantages:

- Reduction in manipulation.

- Increased shelf-life.

- Minimization of waste.

- Increased productivity.

- Ideal for automated application systems.

- Possibility of mixing with other solid ingredients

FLOW CURVE AT 6ºC

EXCELLENT FREEZE – THAW STABILITY

Quescrem Plus supports any freezing – thawing cycle without altering its structure or releasing free water. Its visual appearance and culinary properties remain unchanged even with slow freezing and forced thawing

DESIGNED TO WITHSTAND EVERYTHING!

After freezing (-18 ºC) and subsequent thawing ( 40 ºC)

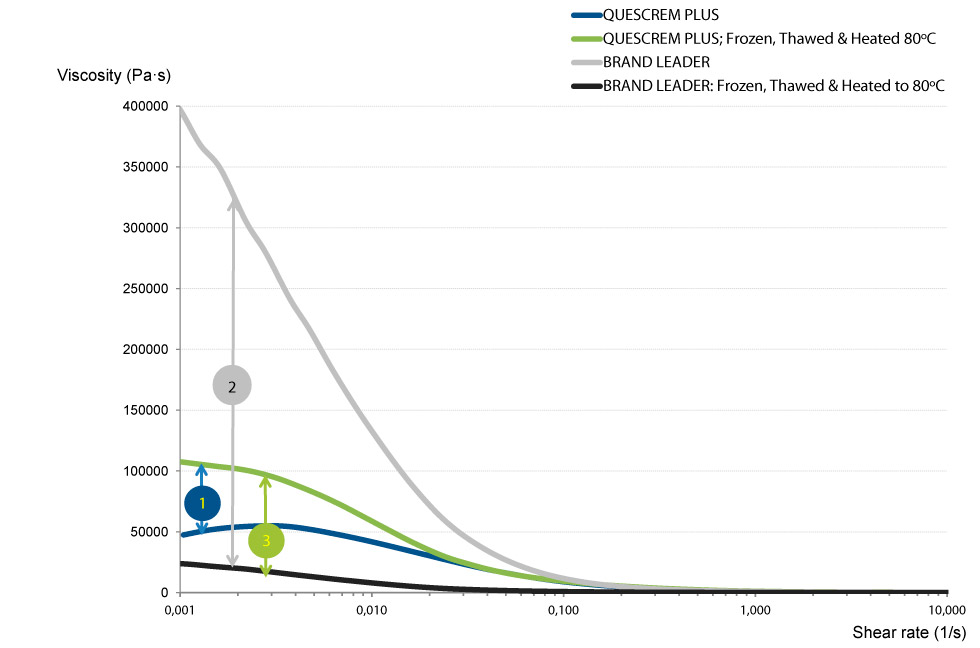

FLOW CURVE AT 6 ° C

(After freezing (-18 º C) + thawing and subsequent heating (80 º C)

2 After freezing and heating to 80 °C the Brand Leader cream cheese lost its physical structure, reducing its viscosity between 4 to 10 times.

3 The QUESCREM PLUS cream cheese after freezing and heating to 80 ° has between 5 and 10 times the viscosity of the product category market leader, which indicates that it much better withstood all thermal processes to which it was submitted.

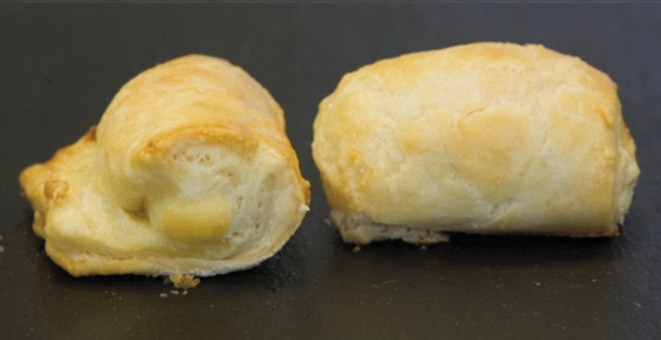

HEATING RESISTANCE

Quescrem Plus has been developed to withstand all types of uses which require easy application, freezing and heating process used in the food industry (baking, frying and cooking) without losing its shape and its textural characteristics

DEVELOPED TO SUPPORT INNOVATION!

Neapolitan stuffed with cheese, frozen and then baked at 250 ° C.

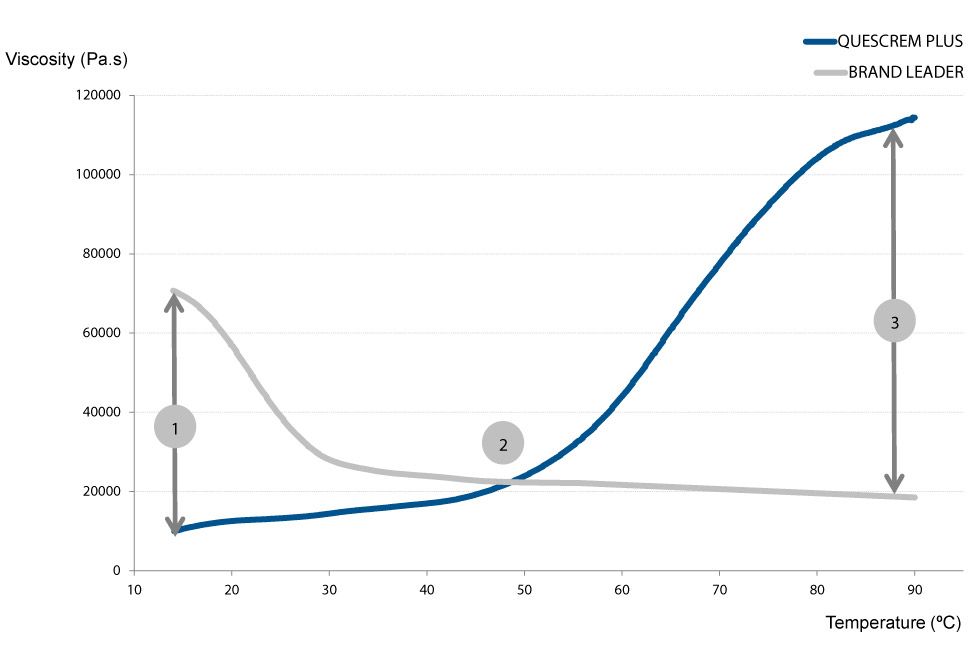

Evolution of viscosity with change in temperature (15 - 90 ° C)

2 When heating, the viscosity of both cheeses changes. The QUESCREM PLUS harden while the brand leader competitor sample, is liquefied. Upon reaching a temperature of 50 ° C the viscosity of the QUESCREM PLUS exceeds that of market leader.

3 With the temperature increase Quescrem Plus continues to harden, while the market leader becomes less and less consistent. At 90 °C the viscosity of Quescrem Plus is 6 times higher than the Brand Leader cream cheese.